tablet thickness test definition|pharmaceutical tablet testing : chain store Tablets are made utilizing various shape tooling; a significant test is the control of the thickness of each tablet using a particular shape of tooling. We measure the thickness of . WEBAnálise. A 8/10 2023, a Guaireña jogou com a Libertad na Division Profesional. 74/5000 A partida terminou 1 - 5 para Libertad . Uma vez que o jogo já terminou, sugerimos-te que .

{plog:ftitle_list}

Resultado da 9 de ago. de 2023 · Não existem reclamações sobre trioderm plus porque ele foi criado após exaustivos estudos e escolhas minuciosas de seus .

A variety of methods are used for the evaluation of tablets or conducting quality control tests of tablets. All of the quality control tests of tablets or evaluation tests of tablets are classified into three categories: A. Non-Pharmacopoeial or Non-Official Tests or In-House Tests of Tablet: 1. Appearance/ Description 2. . See moreThe choice of these tests and their specification depend on the formulator during drug product development and these tests are not restricted or specified in . See more

1. Center for Drug Evaluation and Research (CDER) (2015). “Guidance for Industry: Size, Shape, and Other Physical Attributes of Generic Tablets and . See more Tablets are made utilizing various shape tooling; a significant test is the control of the thickness of each tablet using a particular shape of tooling. We measure the thickness of .

The thickness of a tablet should be controlled within ±5% variation of a standard value depending on the size of the tablet. Other non-pharmacopoeial tests include measurement of tablet diameter, porosity, liquid . The test that is used to measure how thick the tablet is, known as the tablet thickness test. Tablets are manufactured using different shapes of tooling and an important . Hardness, friability, thickness, disintegration, weight variation, content uniformity, and dissolution are important quality control tests conducted on tablets. Hardness .83 mm oval tablets and found the transit times for the 8 mm round tablet to be significantly shorter 84 than for 11 mm round and 14 mm x 9 mm oval tablets (p<.02 and p<.04, respectively).

A tablet’s thickness has an impact on both its size and shape. As a tablet grows larger, it becomes harder to administer, hence the size and shape of the tablet are critical factors in patient compliance. A micrometer caliper is .

An index has been developed that factors tablet hardness with the load to break that tablet to create a numerical value that can be used to compare chewable tablets for their ease of being.

The labels in Fig. 3 indicate tablet thickness, illustrating that the results are dependent on tablet geometry. By definition, a material property is independent of test .This test is provided to determine whether tablets, capsules, or granules USP 1-Aug-2019 disintegrate within the prescribed time when placed in a liquid medium at the experimental .The thickness of individual tablets may be mea-sured with a micrometer, which permits accurate mea-surements and provides information of the variation between tablets. Tablet thickness should be controlled within a +_5% variation of a standard value.Any varia-tion in thickness within a particular lot of tablets orThe thickness of a tablet is only variables. Tablet thickness can be measured by micrometer or by another device. Tablet thickness should be controlled within a ± 5% variation of standard value. Organoleptic properties:- Color distribution must be uniform with no mottling. For visual color comparison compare the color of sample against .

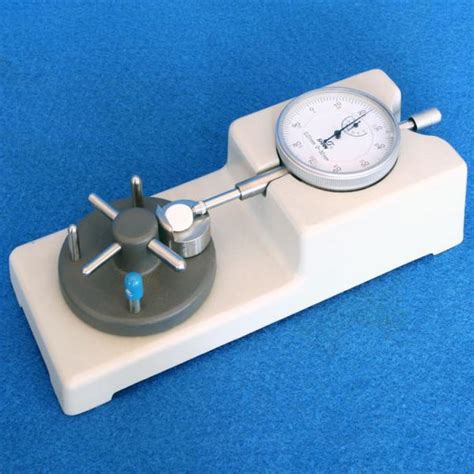

Tablet Thickness Testing . Easy-to-operate and portable tablet thickness testers for busy production environments View More Details Tablet Thickness Tester 547 ; Tablet Thickness Tester 700 ; Digital Caliper Model ."Tablet hardness" is a measure of the force required to break a tablet in a test apparatus that places the tablet under a tension or bending load. The hardness of a tablet plays a crucial role in its efficacy and overall performance, especially during packaging, shipping, and patient use. It is also an essential aspect of tablet quality control.Tablet hardness testing is a laboratory technique used by the pharmaceutical industry to determine the breaking point and structural integrity of a tablet and find out how it changes "under conditions of storage, transportation, packaging and handling before usage" [1] The breaking point of a tablet is based on its shape. [2] It is similar to friability testing, [1] but they are not the . Figure 4: Fracture test on tablet (CT3 Analyzer, Brookfield Engineering). Fracture test. The fracture test is accomplished by driving a smaller hemispherical ball probe into the flat surface of a solid tablet (see Figure 4).A suitable probe deformation distance must be chosen to avoid base effect, which is the external influence of the substrate surface on which the tablet .

Compressed tablets are prepared by the application of high pressures, utilizing steel punches and dies, to powders or granulations. Tablets can be produced in a wide variety of sizes, shapes, and surface markings, depending upon the design of the punches and dies. Capsule-shaped tablets are commonly referred to as caplets.Bioevopeak Tablet Thickness Testers, make the laboratory smarter, more accurate, safer and more convenient. Skip to content. We rebranded from Bioevopeak to Infitek! . Range of test tablet: 0~30mm; Details. Thickness Tester, THKT-3 Test range : (0~5)mm; Test accuracy : ±0.01mm; Type of capsule : 00,0,1,2,3,4 type capsule; Details.Find the best tablet for your needs. Smartphones Compare Laptops Compare CPU GPU SoC Ranking. Beta. Compare Tablets. This page enables you to perform detailed side-by-side tablet comparisons by real-world tests, technical specs, and features. Find the ideal device for your personal use cases: study, work, entertainment or gaming.

During testing, a tablet is placed in each of the six tubes of the basket, and through the use of a . Tablet thickness is determined by the diameter of the die, the amount of fill permitted to . The labels in Fig. 3 indicate tablet thickness, illustrating that the results are dependent on tablet geometry. By definition, a material property is independent of test specimen size. Some underlying assumptions of the test method are presented below. 4. Dissolution test: Drug should be released from tablet in a controlled and reproducible way. Weight variation, thickness & diameter: The appearance of tablet should be elegant & its weight, size & appearance should be consistent. Hardness & friability: The tablet should show sufficient mechanical strength to withstand fracture & erosion during manufacture .

Thickness is an important Quality test for tablet packaging. A very thick tablet affects packaging either in blister or plastic container tablets. Thickness is determined by a micrometer or sliding caliper. Tablet thickness should be controlled within a ±5% variation of the standard value. Tablet Hardness: The Tablet Hardness test is one of the most important in-process tests for tablets which is performed at the start & in between at specified time intervals during the tablet compression operation. The tablet hardness test is performed after line clearance during in-process testing and we don’t start compression operation until the tablet .

water content test for tablets

tablets thickness test

83 mm oval tablets and found the transit times for the 8 mm round tablet to be significantly shorter 84 than for 11 mm round and 14 mm x 9 mm oval tablets (p<.02 and p<.04, respectively). 16. In

11/22/2016 32(2) Second Interim Revision Announcement: <1216> TABLET FRIABILITY http://www.usppf.com/pf/pub/index.html 1/3 1216 T AB LE T FRIAB ILIT YHardness Testing of Pharmaceutical Tablets A technical primer for attorneys By Alberto Cuitiño Professor, Rutgers University 1. Introduction: What is harness testing? . across the diametral line is uniform for a disk of radius R and thickness t made out of an infinitely stiff material. This theoretical result is the centerpiece for the

tablet thickness measurement

in which X is the tensile strength, F is the breaking force, D is the tablet diameter, and H is the tablet thickness. Because only tablets that fail in tension are counted, the data are based on tablets that fail in a consistent way. Thus, reproducibility of data should be enhanced when compared to conventional breaking-strength testing.

tablet thickness limits

Tablet thickness. You can measure the tablet thickness using either mechanical or digital instrument. However, you can use a micrometer to measure the thickness of individual tablets. Knowing the tablet thickness is essential for tablet packaging. Very thick tablets have an effect on the packaging either in plastic containers or blisters. From measuring weight, thickness, and diameter/length to evaluating hardness and beyond, Tablet Hardness Testers offer a comprehensive analysis of tablets in various shapes and sizes. These devices utilize advanced technologies, such as constant speed and force measuring principles, to provide accurate and reliable measurements, eliminating the .Tablet Hardness Testing is also known as the “Crushing Strength Test“. Tablets must have a specific level of strength or hardness in order to withstand mechanical shocks during manufacturing, packaging, and shipping. The force required to break a tablet in a diametric compression test is known as tablet hardness. What are the Factors .Testing tablet hardness is more than ensuring the mechanical integrity of produced tablets during subsequent processes. Because the hardness of a tabletdirectly relates to all other physical parameters, it is a fast and efficient test that indicates whether specifications such as disintegration time and friability will be met. .

The test to determine tablet friability involves subjecting a sample of tablets to mechanical stress by rotating them in a friabilator or friability testing apparatus. The friabilator consists of a drum or a basket in which the tablets are placed, and the apparatus rotates the tablets at a specific speed for a set period. .

tablet thickness lab results

A tablet’s thickness has an impact on both its size and shape. As a tablet grows larger, it becomes harder to administer, hence the size and shape of the tablet are critical factors in patient compliance. . Disintegration test for Tablet: The U.S.P. apparatus used for the disintegration test for tablets includes 6 glass tubes that are 3 .Tablet Thickness Testing. Easy-to-operate and portable tablet thickness testers for busy production environments. Copley’s range of calipers and tablet thickness testers are simple and easy-to-use instruments, designed for use by the press operator on the compression floor. 12. Inconsistent Thickness. Inconsistent thickness is one of the most common defects in tablets. It refers to variations in the tablet thickness within a batch or across different tablets. Inconsistent thickness can impact the overall quality, functionality, and appearance of the tablets. Causes of Inconsistent Thickness:

Confira agora o resultado do segundo sorteio de hoje, segunda-feira dia 26 de fevereiro do jogo do bicho Nordeste Monte Carlos de Pernambuco (PE), os números sorteados são publicados logo assim que ocorre o .

tablet thickness test definition|pharmaceutical tablet testing